Thomas Savery’s 1698 Engine

At about 1650, English inventor and engineer Thomas Savery was born. Savery invented the first commercially used steam powered powered device, a steam pump which is often referred to as an “engine“. Savery‘s “engine” was a revolutionary method of pumping water, which solved the problem of mine drainage and made widespread public water supply practical.

Rowing of ships with greater ease…

Thomas Savery became a military engineer and was promoted to Captain in 1702. He used to spend his free time with mechanical experiments. Savery filed a patent in 1696 for a glass or marble polishing machine. Another patent was filed for “rowing of ships with greater ease and expedition than hitherto been done by any other”. However, it was dismissed early due to negative reports.

Predecessors of the Steam Engine

In 1698, Thomas Savery patented an early steam engine. Long before Savery, Hero of Alexandria described the aeolipile during the 1st century AD which is today considered to be the first recorded steam engine. In Ottoman Egypt, the inventor Taqi al-Din Muhammad ibn Ma’ruf described a steam turbine device for rotating a spit in 1551. In 1606, the inventor Jerónimo de Ayanz y Beaumont obtained a patent for a rudimentary steam-powered water pump.

Thomas Savery (1650 – 1715)

A new invention for raising of water…

Savery’s engine was described as “A new invention for raising of water and occasioning motion to all sorts of mill work by the impellent force of fire, which will be of great use and advantage for draining mines, serving towns with water, and for the working of all sorts of mills where they have not the benefit of water nor constant winds.” He demonstrated it to the Royal Society in 1699. In 1702, Savery described it in his book The Miner’s Friend; or, An Engine to Raise Water by Fire. In it, Savery claimed that the engine could pump water out of mines.

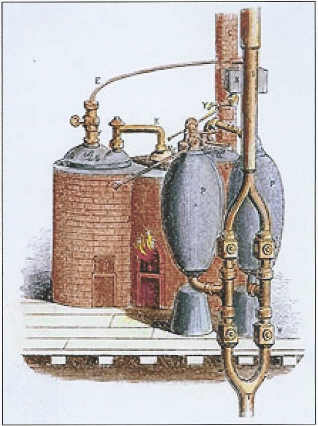

Operation of the Steam Engine

Thomas Savery’s engine was operated by first raising steam in the boiler. Then, the steam was admitted to one of the first working vessels, allowing it to blow out through a downpipe into the water that was to be raised. When the system was hot and therefore full of steam the tap between the boiler and the working vessel was shut, and if necessary the outside of the vessel was cooled. This made the steam inside it condense, creating a partial vacuum, and atmospheric pressure pushed water up the downpipe until the vessel was full. At this point the tap below the vessel was closed, and the tap between it and the up-pipe opened, and more steam was admitted from the boiler. As the steam pressure built up, it forced the water from the vessel up the up-pipe to the top of the mine. Except for the taps, the engine had no moving parts and no piston.

Problems

Unfortunately, there were a few problems with this engine. Every time water was admitted to the working vessel much of the heat was wasted in warming up the water that was being pumped. Also, the second stage of the process required high-pressure steam to force the water up, and the engine’s soldered joints were barely capable of withstanding high pressure steam and needed frequent repair. Thirdly, to clear water from a deep mine would have needed a series of moderate-pressure engines all the way from the bottom level to the surface. Another problem was that water was pushed up into the engine only by atmospheric pressure, so the engine had to be no more than about 30 feet (around 9 m) above the water level.

Exploitation of the Steam Engine Patent

Savery’s patent from 1698 guaranteed him 14 years of protection and one year later the so-called Fire Engine Act was passed which extended his protection for a further 21 years. His patent covered all engines that raised water by fire, therefore it played a significant role in shaping the early development of steam machinery in the British Isles. Due to the act, Thomas Newcomen who himself began developing steam engines, had to form a partnership with Savery. In 1712, Newcomen’s more advanced engine was developed and marketed under Savery’s patent. The Fire Engine Act did not expire until 1733, four years after the death of Newcomen. In 1702, Savery’s engines were ready for use. One was set up at York Buildings in London and another was built to control the water supply at Hampton Court, while another at Campden House in Kensington operated for 18 years.

Steam Engine – How Does It Work, [7]

References and Further Reading:

- [1] Thomas Savery at Britannica Online

- [2] Thomas Savery at Famous Inventors

- [3] Thomas Newcomen and the Steam Engine, SciHi Blog, February 26, 2018

- [4] Matthew Boulton and James Watt’s Steam Engines, SciHi Blog, August 17, 2017

- [5] James Watt and the Steam Age Revolution, SciHi Blog, January 5, 2018

- [6] Thomas Savery at Wikidata

- [7] Steam Engine – How Does It Work, Real Engineering @ youtube

- [8] Savery, Thomas (1827). The Miner’s Friend: Or, an Engine to Raise Water by Fire. S. Crouch.

- [9] Edward Irving Carlyle, Thomas Savery, Dictionary of National Biography, Errata (1904), p.241.

- [10] Timeline for the history of the Steam Engine, via Wikidata and DBpedia

Pingback: Endüstri 4.0'a Giden Yol - FoxRatings | FoxRatings

There was one of Savery’s engines installed and working for a time located in the property where I currently live in a part of an outbuilding which, over the last 300 years, has been at times, a cloth dyers, millhouse, maltworks, flour mill and various occupations including a brewery operating sometimes in tandem. The engine was situated in a small isolated workroom immediately above an underground stream to raise water for the dyers and for the workers and household of the owner. There is a primitive drawing made in the plasterwork with a sharp point which I have photographed and is barely visible, sufficient to be able to identify the component parts and the flowing underground stream.